Measuring is a lifelong journey

Michael Cooper

DateFebruary 2023

In 2023, it is a disappointing fact that most product packaging is still designed to be single use. This means that after you’ve eaten your lunch-break sandwich and placed the container in the bin, the packaging won’t be reused or recycled. According to the US Environmental Protection Agency, food and food packaging materials make up almost half of all waste that goes into landfill. Estimates suggest that around two-thirds of packaging materials for food aren’t recyclable and only one-third is even remotely sustainable.

Closer to home in Australia, a study conducted last year by the WWF found that more than 80% of food packaging cannot be put into home recycling bins. WWF-Australia concluded this based on the recyclability of packaging in 82 popular food products. The study found that under 20% of products were entirely kerbside recyclable, around 55% must have certain components taken to a collection point, and around 25% are difficult to collect and recycle, with numerous examples of over-packaging and bad packaging design.

Most forms of food packaging use a lot of resources like water, chemicals, petroleum, minerals, wood and energy to produce. Their manufacture frequently generates high levels of greenhouse gas emissions and an abundance of wastewater containing toxic contaminants.

Pain in the glass

The manufacture of glass requires raw materials to be melted by the burning of fossil fuels, such as natural gas, fuel oils and liquefied petroleum gas. GHG emissions that result from the combustion of fuels include sulphur oxides and nitrogen oxides. Emissions that result from the recrystallization of the materials then include fine particulates that can contain heavy metals such as lead and arsenic.

Heavy metal

In metallic packaging, the required aluminium is the result of bauxite that is smelted into alumina, an energy-intensive process that requires the use considerable volumes of water and eventuates in a noxious toxic sludge.

Paper weight

Paper packaging uses wood that is required to be milled into pulp using either mechanical or chemical processes. It also uses plant fibres like cotton, linen and hemp, as well as grasses like wheat and straw. The mills required for the process use significant amounts of energy and water, which in turn result in large volumes of toxic wastewater.

Plastic (not so) fantastic

The main raw materials for plastics production are natural gas or the refinement of crude oil. There are seven types of plastics polymers that account for over 70% of all global plastic production, including polypropylene, polystyrene, polyvinyl chloride, polyethylene terephthalate and polyethylene, all of which are originat from fossil fuels.

Whether it is plastic in our oceans or GHG emissions related to manufacturing, the environmental impact of food packaging is immense.

Follow the data

If your business relies on the sale of packaged products, it is increasingly important to firstly understand the impact that your company is having on the planet, and the most effective method of gathering the data is a Lifecycle Assessment.

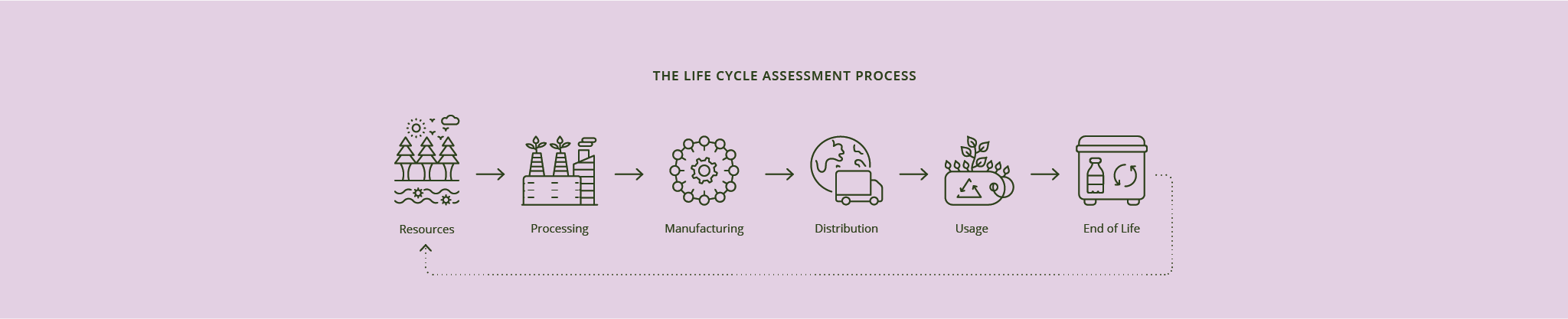

A Life Cycle Assessment analyses the environmental effects related to the whole lifespan of a piece of packaging. The main stages of an assessment cover raw material extraction, processing, manufacturing, distribution and ultimately disposal. The assessment also presents the other phases used to go to market, and it supports decision-makers in adding more sustainable considerations to their products and packaging.

A Lifecycle Assessment will measure the environmental performance of packaging and/or product design and create an accurate baseline to improve upon in future iterations. Accurate and reliable data is gathered on numerous environmental indicators, including resource consumption and the metrics of emissions.

LCAs are therefore an important tool in helping to discover problematic areas that a business needs to improve their environmental impacts. When an LCA is undertaken, a company is often compelled to revaluate all stages of their design development, from the selection of raw materials to the mining of these materials to the completion of the material’s life cycle.

Life cycle assessments help manufacturers to make vital decisions in packaging from the outset. For example, making packaging lighter can reduce freight costs significantly and an LCA can provide telling data on materials that can lead to positive savings for the business. Carbon Neutrals’ life cycle assessment professionals use the latest leading-edge tools to provide a holistic approach to consumer product manufacturing.

Learn more

The goal of a Life Cycle Assessment for a business is to understand the environmental impact of the product and making changes to reduce that impact. By doing an LCA, a business can be more environmentally friendly and help protect the planet. Arrange a Lifecycle Assessment for your business in 2023.

Explore stories in the world of sustainability, carbon and climate change.